MOTORS

These are the common design values for all our motors:

- In-house engineering

- Seamless integration

- California Design, Swiss Engineered

For Riders, the motor plays a significant role since they directly interact with it when pedaling. The following ride characteristics apply to all motors:

- It`s you, only faster

- Natural ride feel

- Smooth, powerful & as quiet as possible

- Custom firmware

- Consistent support over a broad cadence range

- No added drag without assistance

The icing on the cake are our connectivity options.

- Mission Control app to customize and control the Turbo system

- Connect to the built-in ANT+ sensors to see speed, cadence and Rider power on any suitable ANT+ device

SL Motors: Common Design Features

Name & Development

- Specialized SL 1.2 and SL 1.1

- Custom motors, engineered in a close partnership with a premium automotive supplier; Specialized led the way around design, integration and firmware development

- Over 100 engineers involved in mechanical and software engineering

- Custom firmware for each motor, developed by Specialized

- Background to firmware development: around 30-40 firmware iterations are usually needed to get the intended ride feeling; having a custom firmware requires a lot of effort, but pays off since it has substantial influence on the ride feel

SL Motors: Hardware Features

Working principle

- Brushless 48V motor, geared

Weight

- Around 1.95 kg

Housing

- Magnesium housing for lower weight; corrosion-resistant surface treatment

Motor covers

- Attaches to the underside of motor

- Secured differently, depending on bike family

Mounting

- Direct to frame with 6 bolts, 3 each frame side

- Mounting varies slightly between the Turbo SL bike families

- For bolt dimensions, see schematic on Service Website/B2B, filed under each Turbo bike

Connectors

- 2 connectors

- (1) Power supply from main harness/battery

- (2) Speed sensor cable

Integrated Sensors

- These sensors send their data to the bike display and can be read via external ANT+ devices

- Rider power (highly accurate dual sided torque sensor)

- Speed

- Cadence

Freewheel & Internal Design

- Instant engagement freewheel technology

- No lag when beginning to pedal

- No drag when there is no motor support

- Critical circuit board is not located next to actual motor to avoid thermal issues; generally, motor cannot overheat thanks to clever design features

Bearings

- Double sealed bearings + additional radial seal for best and lasting sealing results

- Despite great sealing, we only have about 1.5 watts loss through motor seals, which means a SL rides like a normal bike when powered off (normal bottom brackets also have around 1 watt)

Protection Rating

- High IP67 ingress protection rating through double sealed bearings + additional radial seal on both sides of unit (yet, pressure washing not recommended)

Thermal Management

Under normal riding conditions, most riders will never experience power reduction due to overheating. In extreme conditions, the motor is designed to reduce power slowly, but it will most likely not get into a temperature range where it shuts-off completely. Bear this in mind:

- The system is very efficient and offers best-in-class heat management

- Under extreme motor temperatures, the system first slightly reduces motor power, which will be hardly noticeable; it would reduce power more noticeably when temperature rises further

- Heat build-up primarily depends on

- Terrain conditions (gradient, surface)

- Motor support level (higher Support/Peak Power = more heat)

- System weight

- Ride time with high loads

- Ride style (low cadences create more heat)

- Ambient temperature

- The rider cannot damage anything because the system is self-protecting, but can act in a way to avoid unnecessary heat build-up by:

- Pedaling in a higher cadence spectrum (75rpm +)

- Not leaving the bike in the sun when not riding

- Avoiding unnecessary weight/resistance

Light Connection

- SL motors do not feature light ports at the motor

- Lights connect to the `Y-SPLITTER FOR LIGHT` at display (S216800001)

- 12 V only, 8 W/650 mA max.

- For details, refer to the Turbo Studio Knowledge Base article `Guideline to connecting wired lights´

Warranty

- 2 years (from purchase date)

- Important: Please contact your Rider Care / Service team for Assisted Purchase offers for all issues related outside warranty

Type Overview

| Criterion | Specialized SL 1.1 | Specialized SL 1.2 |

|---|---|---|

| Hardware & Firmware Features | Custom motor, engineered in close cooperation with our premium motor partner Unique hardware features: 3-piece magnesium housing Crank interface similar to ISIS standard, but not identical; made for custom Praxis crank Spider interface: teethed interface for custom spider, held by retaining ring; 3mm pinch bolt clamp screw Unique firmware features Dedicated firmware, reflecting the SL 1.1 power curves Exponential behaviour: support settings are exponentially differentiated based on rider torque, resulting in this: Modes Turbo, Trail and Eco behave differently if you set them to identical values in Mission Control. Example: setting 80/80 in Turbo mode would require less rider input for full motor assist compared to 80/80 in Trail or Eco | Custom motor, engineered in close cooperation with our premium motor partner Unique hardware features: New gearbox design (reduced noise, reliable power delivery) New 2-piece magnesium housing with honeycomb structure (noise dissipation) New spider interface with SRAM DUB lockring (eliminates movement) New crank spindle with SRAM DUB interface New gloss coating Unique firmware features Dedicated firmware, reflecting the increased power of the SL 1.2 motor Allows riders to more sensitively control motor power Most natural feel when accelerating and decelerating Linear behaviour: support settings are evenly differentiated based on rider torque, resulting in this: modes Turbo, Trail and Eco behave identically if you set them to identical values in Mission Control. Example: setting 80/80 in Turbo mode would have the same character as 80/80 as Eco mode |

| Protection Rating | High IP67 ingress protection rating through double sealed bearings + additional radial seal on both sides of unit (yet, pressure washing not recommended) | |

| Approx. Weight | 1.95 kg | |

| Max. Torque | 35 Nm | 50 Nm |

| Max. and Nominal Watts1 (mechanical) | Peak: 240 watts Nominal: 240 watts Nominal and peak performance are identical because the motor can maintain its peak power of 240 W throughout the prescribed test duration (30 minutes) | Peak: 320 watts Nominal: 250 watts |

| Rider Amplification / x times You 2 | 180 % (240 w / 135 w = 1.8) 2x you (simplified) | 237 % (320 w / 135 w = 2.37) 2x you (simplified) |

| Servicing Notes | Use the resources on the Service Website/B2B and in Turbo Studio Service Manager in case of service or replacement (e.g. service instructions or motor replacement video) | |

| Warranty Terms | 2 years | |

Performance Curves

Testing and graph designation

- Multiple samples of SL motors were tested in the independent Velotech test lab and on in the in-house motor dyno

- The y-axis (vertical) represents motor performance

- The x-axis (horizontal) represents the rider cadence (crank rotations per minute/rpm)

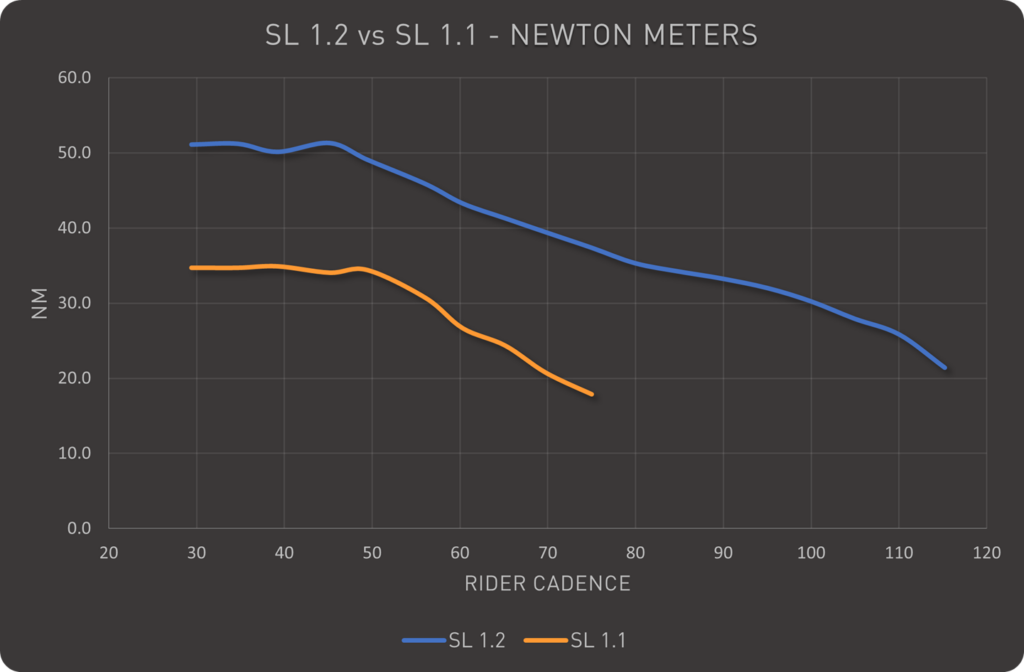

Newton Meters

In simple terms, newton meters determine how fast you accelerate.

Benefits of SL 1.1 and SL 1.2 newton meter curves

- SL motors offer pretty constant torque till rpm 50 for steady, natural acceleration and smooth climbing

- The curves do not drop beyond, but gently decrease in higher cadence spectra; this adds to the smooth and natural ride feel

- The torque behaviour ensures seamless acceleration and climbing, without any power lurches or unwanted sudden drops

SL 1.2 vs SL 1.1 motor (torque)

- SL 1.2 motor

- Offers around 43% more torque vs. SL 1.1

- Maximum torque is 50 Nm

- SL 1.1 motor: Maximum torque is 35 Nm

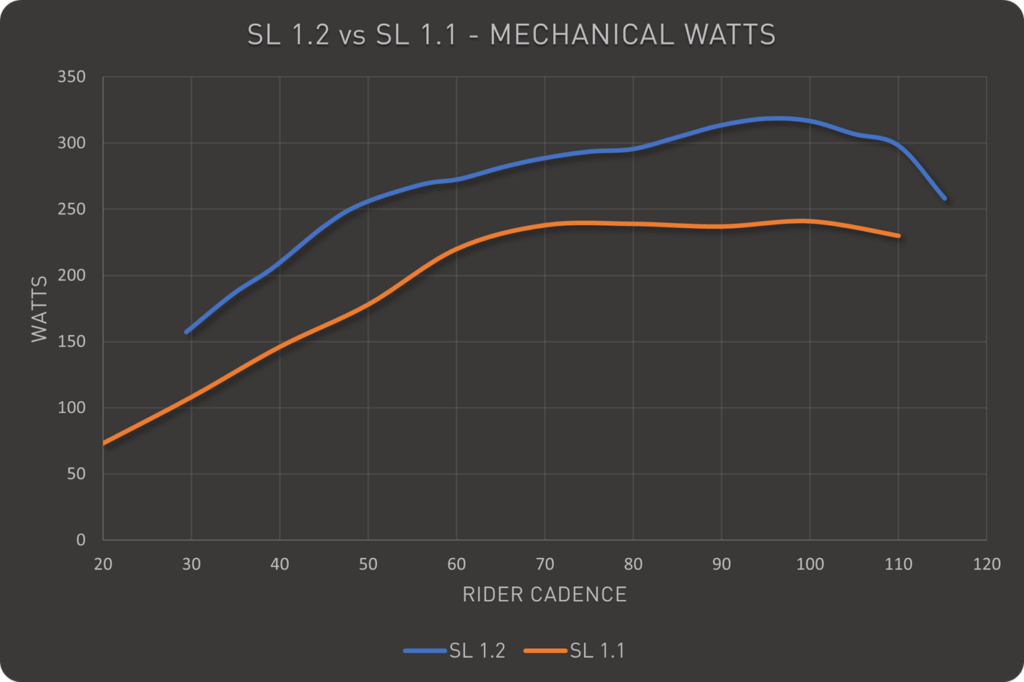

Mechanical Watts

In simple terms, watts determine how easy it is for a rider to maintain speed.

Benefits of SL 1.1 and SL 1.2 watt curves

- The curves rise linearly to then to keep their performance over a broad cadence range. This ensures smooth and consistent power delivery that does not drop

- The graphs show that both motors keep their support over broad cadence bandwidth and provide consistent high assist, also in the upper cadence range

SL 1.2 vs SL 1.1 motor (mech. watts)

- SL 1.2 motor

- Offers around 33% more power vs. SL 1.1

- Max. mech power: 320 watts

- SL 1.1 motor

- Max. mech power: 240 watts

„motor pow me“ as shown on MasterMind TCU

On MasterMind displays, both the mechanical and electrical motor power can be displayed. The metric “mot pow me” (mechanical motor power) on MasterMind TCU is an estimation, based on this calculation:

mot pow me = mot pow el * 0.8 (we use efficiency of 80% across the cadence spectrum).

At cadences 45-55, the electrical output is the highest, which is why riders would see the highest numbers on the display in that cadence spectrum. It is planned to improve the metric “mot pow me” by taking efficiency into account (tbc).

Efficiency

- Both SL 1.1 and SL 1.2 motor offer very good efficiency in a rider`s natural cadence spectrum: anything 75 rpm and higher is recommended

- For both motors, cadence 80 marks a sweet to support power, efficiency and range – at higher cadences, efficiency increases even further; if riders like to pedal at e.g. 90 rpm, they can gain some additional efficiency/range

RPM 75+ supports optimal efficiency and range

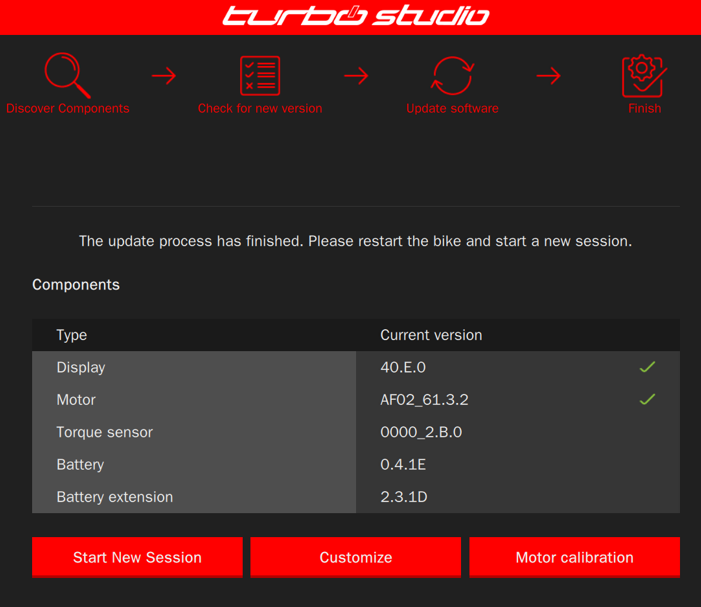

Motor Calibration

General

Both SL 1.1 and SL 1.2 motors feature a torque sensor that is calibrated during the production process. The torque sensor measures rider torque to ensure:

- Accurate calculation of rider power

- Smooth delivery of motor power

Should the torque sensor be out of calibration (torque sensor drift/offset), a rider would see unstable or unrealistic power values and/or experience intermittent or unnatural motor power delivery.

Examples/guidelines:

- The greater the offset, the greater the power reading inaccuracy

- An offset greater than +/- 5 Nm is increasingly noticeable when riding

- If the motor has a negative offset of 10 Nm, the rider will need to provide 10 Nm more input to deliver expected motor support

Calibration

SL 1.1 and SL 1.2 motor have partly different behaviour and requirements with regard to calibration and use of our digital tools.

Criterion | Torque sensor in SL 1.1 Motor | Torque sensor in SL 1.2 Motor |

|---|---|---|

| General | Manual calibration If a torque drift got detected, the motor needs to be calibrated through Turbo Studio. | Self-calibration The SL 1.2 motor uses a learning algorithm and adapts to the rider, which means it is able to self-calibrate while riding. |

| Firmware | No option to see and/or update firmware in Turbo Studio | Torque sensor firmware is visible in Turbo Studio and Bike Inspector. Firmware can be updated together with motor firmware, but will rarely happen. |

| Turbo Studio (calibration) | Generally required for calibration Prompts calibration once bike got connected | Only required in case of a high torque sensor drift Manual calibration only prompted if a higher torque sensor drift (e.g. > 5 Nm) was detected and self-calibration was not successful. If a user clicks on „Motor Calibration“ dialogue box with an info message opens. Message must be confirmed with „Proceed“ to be able to enter the motor calibration feature. |

| Turbo Studio (Event Log) | Both motors log the detection of torque offset in the Event Log. These events can be seen in Turbo Studio after connecting the bike or after uploading the event log through Mission Control. | |

| Mission Control | Torque offset events are not displayed to riders in Mission Control. | |

Turbo Studio captures these different offsets in the Event Log: Recommendations are based on ride feel (a significant positive offset creates a jerky ride feel, whereas a negative offset does not compromise the ride feel).

| Event Log | Offset | Manual calibration recommended/flagged in TS |

| TQSDrift_plus2_5Nm | 2.5 to 5 Nm | No |

| TQSDrift_plus5Nm | 5 to 7.5 Nm | Yes |

| TQSDrift_plus7_5Nm | 7.5 to 10 Nm | Yes |

| TQSDrift_plus10Nm | More than 10 Nm | Yes |

| TQSDrift_minus2_5Nm | -2.5 to -5 Nm | No |

| TQSDrift_minus5Nm | -5 to -7.5 Nm | No |

| TQSDrift_minus7_5Nm | -7.5 to -10 Nm | No |

| TQSDrift_minus10Nm | More than -10 Nm | Yes |